- #Dremel cnc router tool path software software

- #Dremel cnc router tool path software code

- #Dremel cnc router tool path software free

#Dremel cnc router tool path software code

If you don’t want to cut it out, just use thicker material or set your Z axis zero above the part.įor the final part I switched to some finished wood stock from the local hardware store and was pleased to see my 3018 handled it just as easily as the MDF.įull step by step instructions are provided with the G Code along with setup sheets. of this part is an ellipse so I'll just copy an edge to the right location and have the tool step down as it follows that path. Get the most out of your CNC Router with no large upfront.

#Dremel cnc router tool path software software

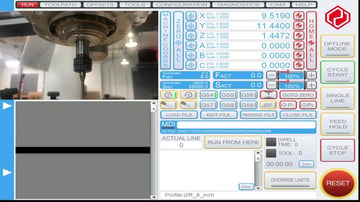

Our CAD/CAM design software provides a unique combination of 2D and 3D design and toolpath capabilities for CNC routers, lasers, plasma, waterjet and knife cutters. I think it's easy to use a 4th axis engraving option which just follows a path. EnRoute is the go-to CNC software solution for everyday cutting, nested-based production, and creative design applications. I programmed the outer profile to go deep enough (-.240”) to cut it out. Just in case the lead times are too long, I designed a fixture to hold the part in the 4th axis because I do have a 1mm ball mill. The 5.5” dimension needs to be orientated along the Y axis. The size of the stock was approx 5” X 5.5” square by 6mm thick. It is very soft, so ideal for using with the 3018 Cnc. The Genimitsu cutters I used are labelled as metric on the box, but when you measure them there is a mixture of both imperial and metric in the set! What Stock material did I use?įor the initial test run of the G code, I used MDF. You can also use 3mm and 1.5mm if you own metric end mills. Just use what you have on hand as long as they are suitable for the material you are using. These are for wood only, which is pretty much the only material the 3018 is capable of machining.Īny similar diameter size tools can be used to get the same result. The tools I used were the Genimitsu 1/8” end mill and the 1/16” end mill. Therefore setting the spindle speed as S1000 will tell the controller on the 3018 to run at 10,000RPM. 1000 being 100% RPM (maximum) and 10 being 1% RPM (minimum). The 3018 software is a little unusual, it has a maximum spindle speed of 10,000 RPM, but is controlled by using a percentage scale of 10 to 1000. The spindle speed, (S1000) near the beginning of the program, can be changed to suit the machine you are running. If your machine is of better quality than a 3018, then the feedrate can be easily increased using the ‘replace’ function available in your text editor of choice, e.g. To work on the 3018 cnc the depth of cut for each pass was kept shallow and the feedrate used was quite slow. The 3018 is a Grbl based machine but they also loaded with no errors on a Mach3 controlled machine and the toolpaths looked as they should in the Mach3 toolpath window. These machines are the ‘lowest common denominator’, meaning, if the programs can be used on this machine, they can be used on any machine. The G code was programmed with the goal of being able to run on a 3018 cnc engraving machine. You will be able to find out what works and what does not work with your machine. I would encourage you to play with the speeds and feeds, especially if you try the programs on different materials. The programs will give you a benchline of what your machine is capable of so you know what to copy or not to copy when you are creating your own programs. If you can cut it with a utility knife, you can cut it faster and more accurately with a Donek Tools Drag Knife.The aim is for you to get familiar with the process of running your Cnc machine successfully and getting repeatable results. Choose from a wide range of sizes, to meet your multiple needs at once. FeatureThe collet has 4 claws, and the holding accessories are more stable. Make a cardboard box, cut leather, cut gasket material, cut pre-preg carbon fiber laminates, and more. SpecificationFits for Dremel rotary tool: 4000,400,3000,300,398,395,8220,8200,8100,800 etc.

They can cut materials up to 1/4in thick and use a standard utility knife blade, minimizing the cost of blades. Our D2 or D4 Drag Knife is the right choice if you want to make a cardboard box. You can cut the same box over and over or create new cardboard box files for any item you sell. Enter the dimensions in the software and it will create the file to cut the box you need.

#Dremel cnc router tool path software free

With this free software, all you need to know are the dimensions of the cardboard box you want to make.

Make a cardboard box with ease using a Donek Drag Knife. Make a Cardboard Box with the Donek Tools Drag Knife. The software is available in g-code and shopbotcode versions.

It can be used to make a cardboard box with 4 flaps top and bottom, just like the ones used for most shipping purposes.

0 kommentar(er)

0 kommentar(er)